IoT Remote Monitoring

Real time, Accurate, and Actionable data

to ensure all operations arein check and

providing the best environments for

optimum yield.

ABS strives to bring valuable and vital data points in to the palm of your hand, allowing for quick and actionable insights. By integrating dedicated IoTs to PMMP and MMMP you can easily and remotely manage key functions in Plantations, Farms, Orchards, Mills, Factories Refineries and more.

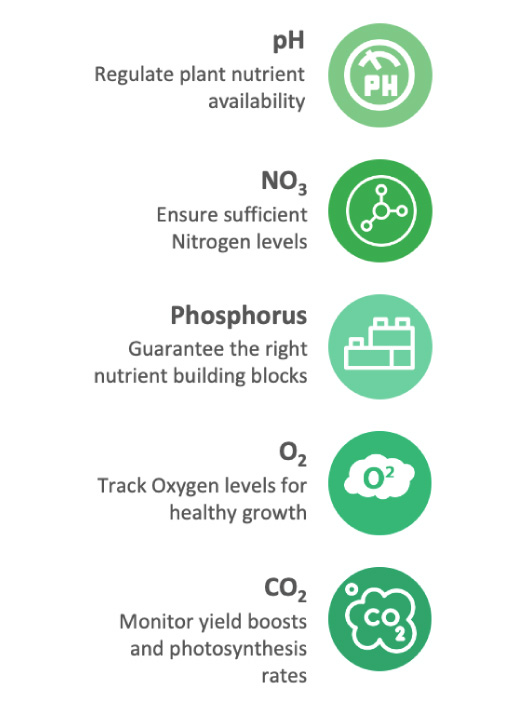

PMMP integrated with our IoT solutions will allow quick and easy traceability of these key touch points:

MMMP integrated with the right IoT sensors in your mill and factory environment will quickly alert unusual activity to provide active supervision and automation of key stations optimizing yield and maintenance.

Alert Supervision System in Oil Palm Mills

Example: Digester Station

FUNCTION

- Digestion is the process of releasing the palm oil in the loose fruit through the rupture or breaking down of the oil-bearing cells. The temperature of the digester is critical and has to be maintained between a preset temperature range to reduce the viscosity of the crude oil in order to facilitate oil removal at the bottom of the digester and to improve the next pressing operation.

MONITORING METHOD

- By installing IoT sensors in the Digester, the sensors will constantly read the operating temperature and will compare it against the preset temperature range. Once the temperature detected by the IoT sensors is above or below the preset temperature range, an Alert Notification is triggered to the mobile device of the Mill Supervision personnel and the countdown timer will be activated.

KEY FEATURES

- The Supervisor concerned will then have to proceed to the location of the problematic Digester and ensure that it is now functioning according to the preset temperature range. He will have to close the open issue in his mobile device.

BENEFITS

- This behavioral change as a result of the Alert Supervision system, will result in the Mill Management team having the visibility to know the time elapsed before the Supervisor responded to that particular problem.

- How long was that particular machine operating out of the preset temperature range.

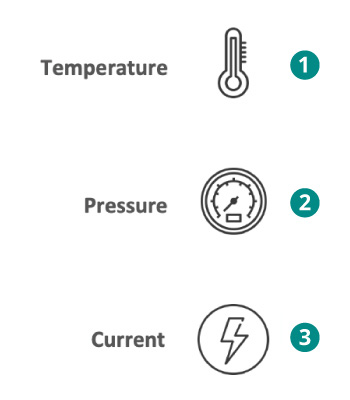

Apart from temperature, the Alert Supervision system could be used to monitor pressure, current, flowrates, level detection and many other parameters in an Oil Palm Mill.

Get started with a

product demonstration

Complete the form to get in touch with one of our experts to see our products in action. We’ll show you how you can ABS systems to drive productivity and yield within your business.